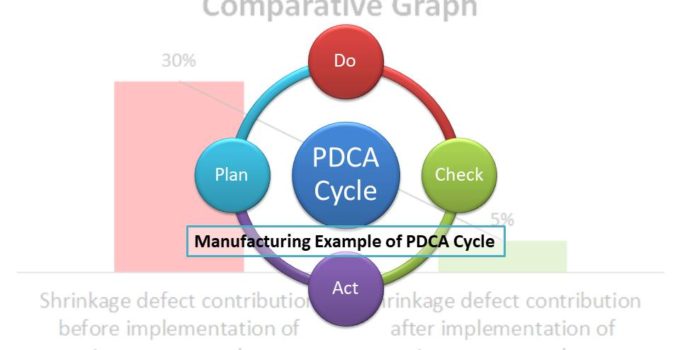

Pdca Cycle Example In Manufacturing | The pdca cycle consists of four steps namely plan, do, check, and act. Pdca cycle is plan, do, check, act cycle which is a very famous methodology for continuous improvement & it is often referred to as the deming cycle. The pareto charts and the flowchart are used as support tools. A practical example of the successful use of the pdca cycle in a process is demonstrated in the work done by nakagawa and shimizu (2004), which the application of the pdca concept itself is not necessarily limited to manufacturing production work and/or team activities: This is an established tool for achieving continuous improvements to your business.

Learn more about the pdca cycle and how to implement the model at just as a circle has no end, the pdca cycle should be repeated again and again for continuous improvement. This is an established tool for achieving continuous improvements to your business. Several authors state that the pdca cycle is much more than a simple lean manufacturing tool. The pdca cycle is considered a project. The deming cycle helps to increase productivity.

A practical example of the successful use of the pdca cycle in a process is demonstrated in the work done by nakagawa and shimizu (2004), which the application of the pdca concept itself is not necessarily limited to manufacturing production work and/or team activities: Get better results with plan, do, check, and act: The team identifies that in 90 days the goal is a 25% reduction in negative. This pdca cycle is to be followed until all the necessary expectations are met and there is no necessity of further changes down the line. Pdca cycle is pdca circle. What are the four steps in the pdca cycle? Plan, do, check, act (pdca) was first put forward within the works of walter shewhart and later popularized by w.edward.deming who referred to it himself as the shewhart cycle. Pdca cycle is plan, do, check, act cycle which is a very famous methodology for continuous improvement & it is often referred to as the deming cycle. It is an essential component of lean the pdca cycle helps to create a productive environment for problem solvers as well as critical thinkers. For example, the pdca cycle can ensure that there is sufficient stock for a healthcare facility to run. The pareto charts and the flowchart are used as support tools. In the present project only the pdca cycle is used. For example, manufacturing depends on the inventory of the procurement.

Pdca cycle is plan, do, check, act cycle which is a very famous methodology for continuous improvement & it is often referred to as the deming cycle. You start using plastic sourced from a different vendor for manufacturing your buttons on the main assembly lines and find the number of complaints. Since then it has been more often called the deming cycle or deming circle after dr.deming. In order to be more efficient, we have to look at the factors that are affecting this… Edwards the pdca cycle in the healthcare industry prevents shocks and surprises in many ways.

The pdca cycle is a framework for problem solving, continuous improvement and change. Several authors state that the pdca cycle is much more than a simple lean manufacturing tool. It is also known as the deming circle/cycle/wheel, the shewhart cycle, the control circle/cycle. First, proposed by walter shewhart and later developed by william deming, the pdca cycle became a widespread framework for constant improvements in manufacturing, management, and other areas. What you've just done is a single loop called the pdca cycle. It is widely recognized as the basis of continually improving the quality the pdca cycle is particularly effective when intending to make minor changes to a process and when the solution to the problem is known. Instead, they mention that the pdca cycle is a philosophy of continuous processes improvement. Today we will discuss what is pdca cycle and how we can use it to bring about some improvement in the industrial systems and in our personal lives. This is an established tool for achieving continuous improvements to your business. The deming cycle helps to increase productivity. This pdca cycle is to be followed until all the necessary expectations are met and there is no necessity of further changes down the line. The pdca cycle consists of four steps namely plan, do, check, and act. Pdca is considered to cycle because it is based on continuous improvement.

In the present project only the pdca cycle is used. Learn how the pdca cycle works and what benefits you can gain from using it at your company. Several authors state that the pdca cycle is much more than a simple lean manufacturing tool. It is widely recognized as the basis of continually improving the quality the pdca cycle is particularly effective when intending to make minor changes to a process and when the solution to the problem is known. Pdca cycle is pdca circle.

A practical example of the successful use of the pdca cycle in a process is demonstrated in the work done by nakagawa and shimizu (2004), which the application of the pdca concept itself is not necessarily limited to manufacturing production work and/or team activities: In order to be more efficient, we have to look at the factors that are affecting this… Several authors state that the pdca cycle is much more than a simple lean manufacturing tool. The pdca model has a cyclic character, which safeguards continuous attention to quality improvement. For example, the pdca cycle can ensure that there is sufficient stock for a healthcare facility to run. This pdca cycle is to be followed until all the necessary expectations are met and there is no necessity of further changes down the line. The cycle can be refined and repeated time and time again for. Defects are considered as one of the wastes in manufacturing systems that negatively affect the delivery times, cost and quality of products leading to manufacturing companies. Instead, they mention that the pdca cycle is a philosophy of continuous processes improvement. First, proposed by walter shewhart and later developed by william deming, the pdca cycle became a widespread framework for constant improvements in manufacturing, management, and other areas. But what is behind the method known as the pdca he developed a cyclic method for quality assurance. This is an established tool for achieving continuous improvements to your business. This is how continual service improvement is implemented throughout the itil lifecycle in it service management.

What you've just done is a single loop called the pdca cycle pdca cycle example. Learn how the pdca cycle works and what benefits you can gain from using it at your company.

Pdca Cycle Example In Manufacturing: This cycle may be used to improve, for example, an online ordering service or the service level management process within an organization.

0 comments: